Engineering Trends

High temperature piping materials in 2050

By 2050, the oil and gas industry is expected to operate in increasingly extreme environments, necessitating the development of advanced piping systems capable of withstanding ultra-high temperatures exceeding 1,000°C. These systems will be crucial for applications such as enhanced oil recovery, hydrogen transport, and geothermal energy extraction.

Advanced Materials for Ultra-High Temperature Piping

Superalloys

Superalloys, particularly nickel-based variants, are engineered to maintain structural integrity at elevated temperatures. Alloy compositions such as AFA superalloys, which contain approximately 35% nickel, have demonstrated potential for use in operating temperatures upwards of 1,100°C. Additionally, multi-principal-element superalloys (MPES), comprising elements like aluminum, titanium, niobium, zirconium, molybdenum, and tantalum, offer enhanced high-temperature performance, strength-to-weight ratios, and resistance to thermal fatigue .

Ultra-High Temperature Ceramics (UHTCs)

UHTCs, including borides, carbides, nitrides, and oxides of early transition metals, are capable of withstanding temperatures above 2,000°C. These materials exhibit high thermal conductivity and resistance to thermal shock, making them suitable for applications such as heat shields and components in nuclear reactors. However, their brittleness and machining challenges currently limit their widespread use in piping systems .

Thermoplastic Composite Pipes (TCPs)

TCPs, constructed from polymers like PEEK (polyether ether ketone) reinforced with materials such as carbon or aramid fibers, offer a lightweight and corrosion-resistant alternative to traditional metal pipes. While standard TCPs are suitable for temperatures up to 120°C, advancements are being made to enhance their high-temperature performance for applications in subsea oil and gas operations .

Design Considerations for High-Temperature Piping Systems

Thermal Barrier Coatings (TBCs)

TBCs are applied to metallic surfaces to insulate components from high heat loads, allowing for higher operating temperatures while protecting structural integrity. These coatings, typically made of zirconates, can sustain significant temperature gradients, thereby extending the lifespan of components exposed to elevated temperatures .

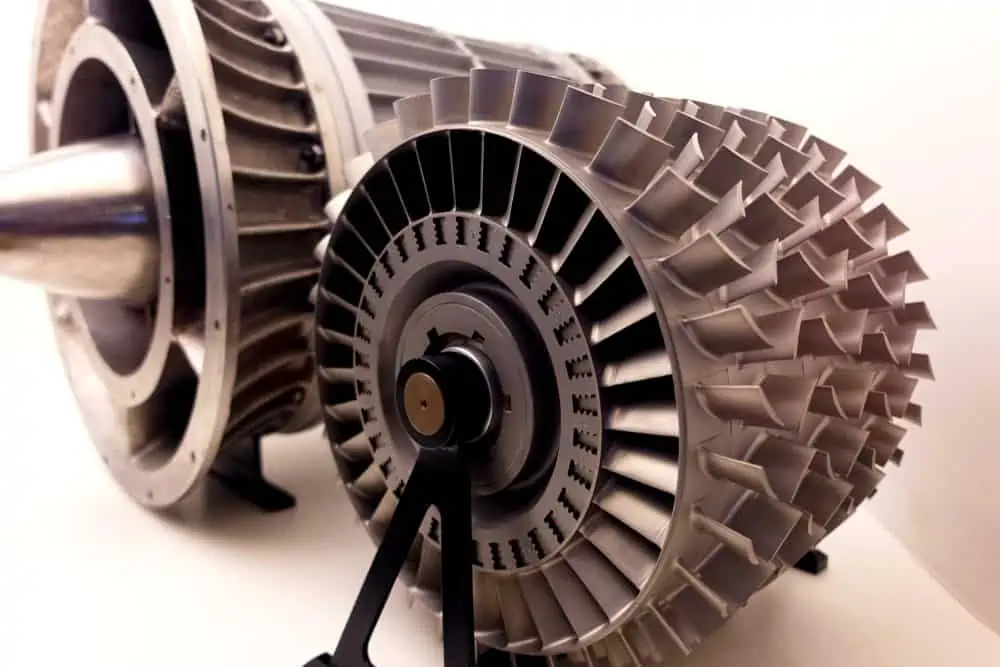

Refractory-Lined Expansion Joints

In systems subject to thermal expansion, refractory-lined expansion joints are utilized to accommodate movement while maintaining system integrity. The refractory lining reduces pipe wall temperatures by 300°F to 450°F, depending on thickness, and is employed in applications such as fluid catalytic cracking units and hot gas turbines .

Future Outlook

As the industry progresses towards 2050, the demand for high-temperature piping solutions will intensify, driven by the need for efficient energy extraction and transportation. The development of materials and technologies capable of withstanding extreme temperatures will be pivotal in ensuring the sustainability and safety of oil and gas operations. Ongoing research into advanced alloys, ceramics, and composite materials, along with innovations in coating and joint technologies, will play a crucial role in meeting these challenges.